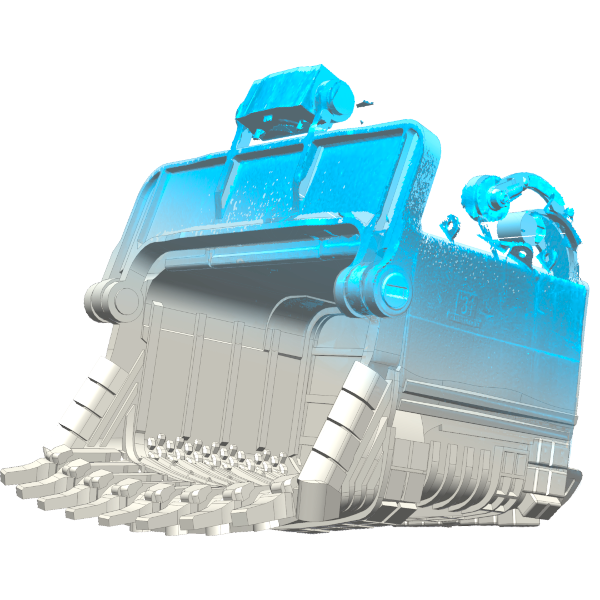

PREMIUM 3D SCANNERS.

PREMIUM POST-SCAN WORKFLOWS.

Powerful and user friendly

- All-in-one software solution.

- Create, refine and analyse ultra-realisitc 3D models

- Reverse engineering and inspection

- AI photogrammetry

ZEISS Quality Software

Explore our software solutions

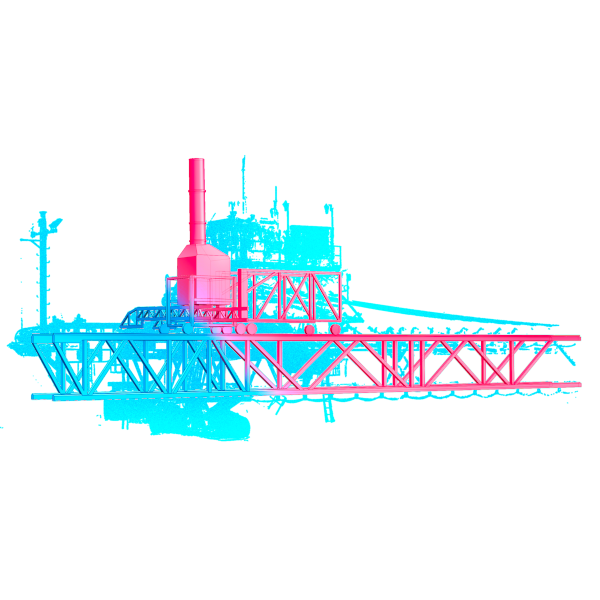

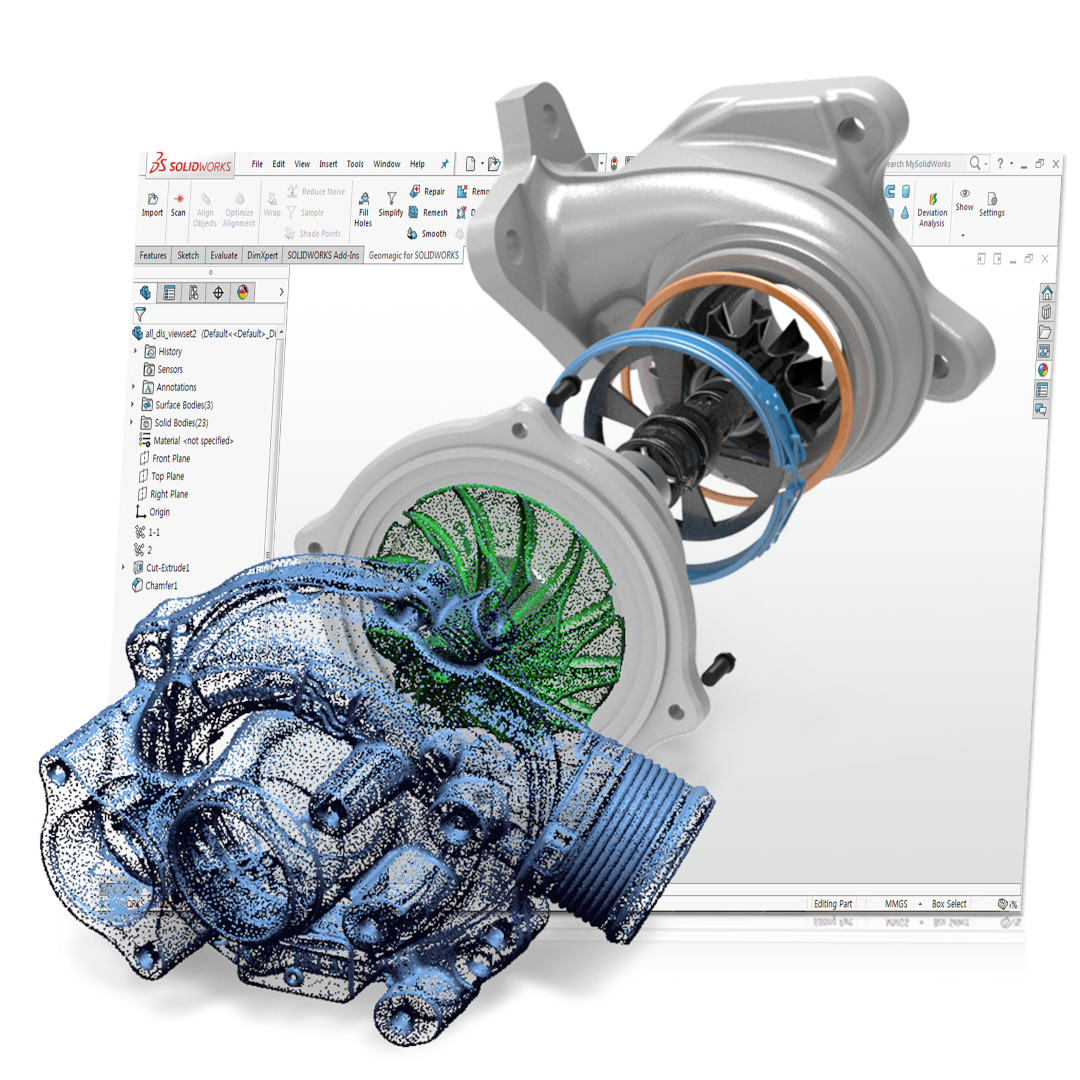

- REVERSE ENGINEERING

- INSPECTION

ZEISS REVERSE ENGINEERING

Surface reconstruction and tool correction

Do you want to create CAD models quickly and simply from polygon meshes or point clouds?

Or do you want to reduce tool optimization iterations in mold making and improve your CAD data for additive manufacturing?

All of this is possible.

- ZEISS REVESE ENGINEERING

- ZEISS TOOL CORRECTION ADD-ON

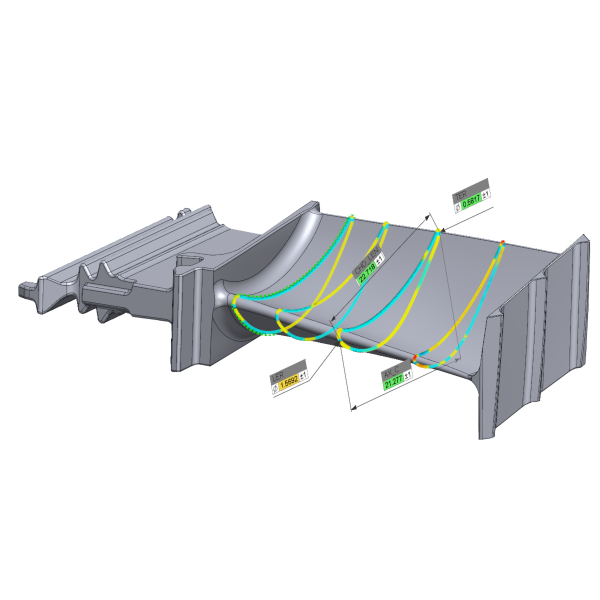

ZEISS TOOL CORRECTION

Correcting the CAD data for tools and 3D printed components

The ZEISS REVERSE ENGINEERING software reduces iteration loops in the tool correction process up to 50%. Simply import three data sets – the existing CAD data of the tool and the product as well as the real measurement data of the product – and then detect areas in need of correction and optimize them with the software.

For 3D printing, only two data sets are required: the CAD data and the measurement data for your printed part. The software analyzes the data and offers solutions for a targeted adaptation of the print data resulting in a dimensionally stable part.

Tool correction is a product option that is available for the REVERSE ENGINEERING basic software.

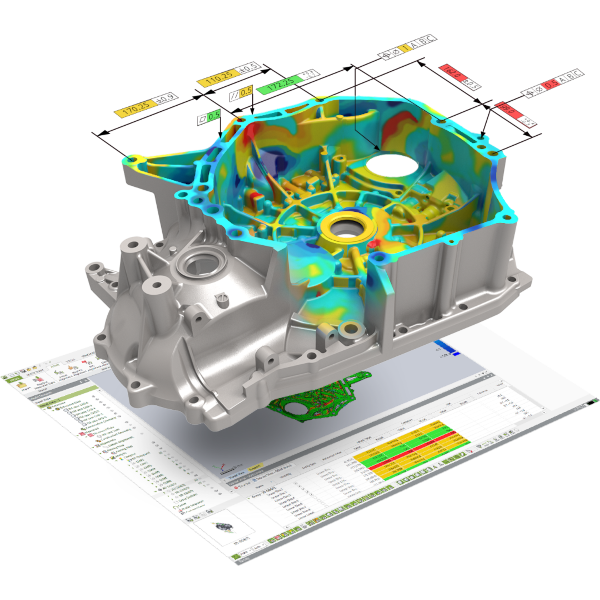

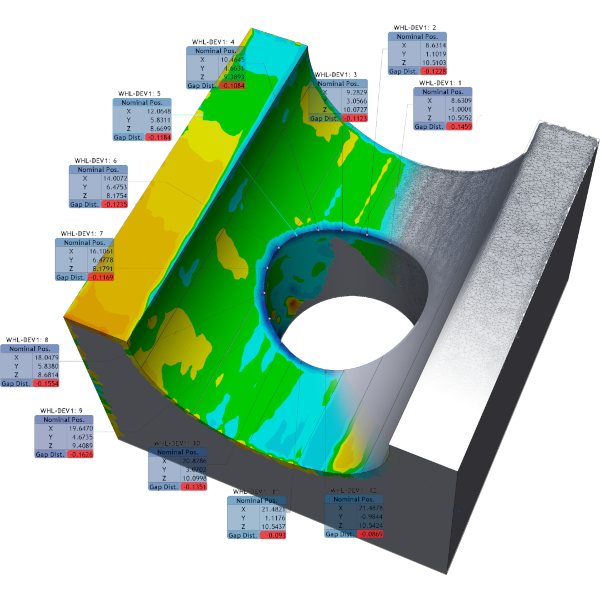

ZEISS INSPECT

One Metrology Software.

Intuitive. Customizable. Automated.

The world of measurement technology is complex. There is a multitude of hardware devices, extensive analyses, and software solutions. Additionally, development, quality control, and manufacturing are subject to high competitive pressure. ZEISS INSPECT is your software to analyze multiple data sources efficiently.

- ZEISS INSPECT Optical 3D Pro

- ZEISS INSPECT Airfoil

- ZEISS INSPECT Virtual Clamping APP

- ZEISS INSPECT Autosurfacing APP